How Vapor Compression Refrigeration System Works

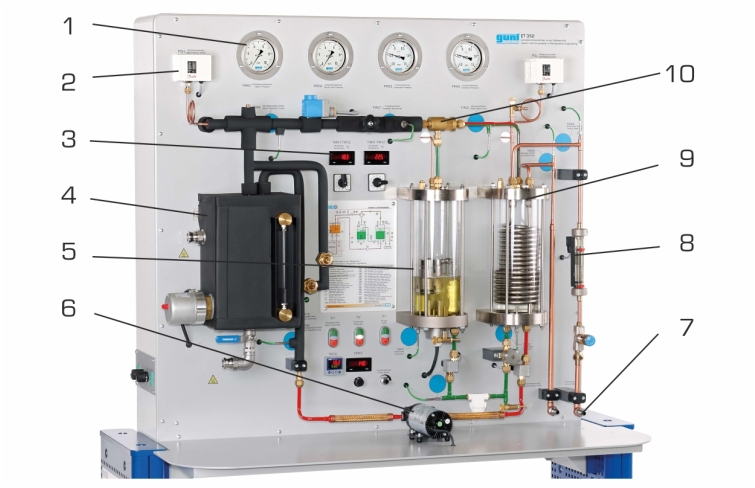

Vapor compression cycle refrigeration is a process which uses the physics of phase change heat transfer. The components in the basic refrigeration system are the Compressor, Condenser, Expansion Valve, and Evaporator.

The heart of the system is the compressor. The compressor takes in a low temperature, low pressure refrigerant vapor and compresses it into a high temperature high pressure vapor. This vapor enters the condenser where heat is removed to either air or water. As the heat is removed the energy stored in the high pressure gas is released and the refrigerant gives up its latent heat as it returns to a hot liquid.

This hot, high temperature liquid exits the condenser and enters the expansion valve, where it undergoes a pressure drop causing some of the hot liquid to vaporize, lowering the temperature of the refrigerant stream. The refrigerant at the exit of the expansion valve is a low temperature two-phase flow.

This two-phase flow enters the evaporator where it is exposed to the heat source. The heat from the source boils off the refrigerant through phase change heat transfer and the low temperature low pressure gas then enters the compressor, completing the cycle.

The high pressure high temperature upper half allows the refrigerant to become significantly hotter than ambient air, forcing heat transfer.

The low temperature low pressure half of the cycle allows the refrigerant to absorb heat from a source that is not as hot as the environment. The compressor does the work to raise the pressure and the expansion valve ensures that adequate pressure is retained in the condenser for heat transfer.

By varying the evaporator, the vapor compression cycle can be used to cool air, liquid, or cold plates.

To create an air cooling system, the evaporator is a refrigerant to air heat exchanger.

To cool liquids, the evaporator is a refrigerant to liquid heat exchanger with the pumped liquid being cooled by the evaporating refrigerant.

Direct Refrigerant cooling is where the refrigerant flows directly through the cold plate. With the evaporator as the coldplate, the devices being cooled have the advantage of phase change heat transfer with minimal temperature rise.

Vapor compression cooling is extremely flexible with the highest efficiency.

How Vapor Compression Refrigeration System Works

Vapor compression cycle refrigeration is a process which uses the physics of phase change heat transfer. The components in the basic refrigeration system are the Compressor, Condenser, Expansion Valve, and Evaporator.

The heart of the system is the compressor. The compressor takes in a low temperature, low pressure refrigerant vapor and compresses it into a high temperature high pressure vapor. This vapor enters the condenser where heat is removed to either air or water. As the heat is removed the energy stored in the high pressure gas is released and the refrigerant gives up its latent heat as it returns to a hot liquid.

This hot, high temperature liquid exits the condenser and enters the expansion valve, where it undergoes a pressure drop causing some of the hot liquid to vaporize, lowering the temperature of the refrigerant stream. The refrigerant at the exit of the expansion valve is a low temperature two-phase flow.

This two-phase flow enters the evaporator where it is exposed to the heat source. The heat from the source boils off the refrigerant through phase change heat transfer and the low temperature low pressure gas then enters the compressor, completing the cycle.

The high pressure high temperature upper half allows the refrigerant to become significantly hotter than ambient air, forcing heat transfer.

The low temperature low pressure half of the cycle allows the refrigerant to absorb heat from a source that is not as hot as the environment. The compressor does the work to raise the pressure and the expansion valve ensures that adequate pressure is retained in the condenser for heat transfer.

By varying the evaporator, the vapor compression cycle can be used to cool air, liquid, or cold plates.

To create an air cooling system, the evaporator is a refrigerant to air heat exchanger.

To cool liquids, the evaporator is a refrigerant to liquid heat exchanger with the pumped liquid being cooled by the evaporating refrigerant.

Direct Refrigerant cooling is where the refrigerant flows directly through the cold plate. With the evaporator as the coldplate, the devices being cooled have the advantage of phase change heat transfer with minimal temperature rise.

Vapor compression cooling is extremely flexible with the highest efficiency.

No comments:

Post a Comment