we’re going to talk about pneumatic actuators. We’ll look closely at the operation and application of the most common pneumatic actuator, the spring/diaphragm linear pneumatic actuator.

An actuator is a device that makes something move or operate. Actuators make life easier for us every day, and they are the workhorses of the industry.

There are three typical types of actuators used in industry as defined by their energy source:

– Electric

– Hydraulic,

– Pneumatic.

A pneumatic actuator converts energy in the form of compressed air into movement. Pneumatic actuators are categorized by their type of motion. They are either Linear or Rotary.

1) A rotary pneumatic actuator can make something move in a circular motion. For example, a rod in a rack and pinion drive system is used to produce rotary motion.

In the Rotary pneumatic actuator category, the Vane style and the Rack and Pinion style are very common.

1-1) Vane Actuators have a cylindrical chamber in which a movable vane is mounted on a shaft. Pneumatic air under pressure applied on one side of the vane causes it to rotate through its stroke.

1-2) Rack and Pinion actuators use a piston attached to rack gear. When pneumatic pressure is applied, the piston and rack move linearly rotating the pinion gear and driveshaft.

2) A linear pneumatic actuator can move something in a straight line. For example, a rod is moved in and out of a cylinder in a linear motion by a pneumatic energy source. In the Linear pneumatic actuator category, the spring/diaphragm style and the piston style are very common.

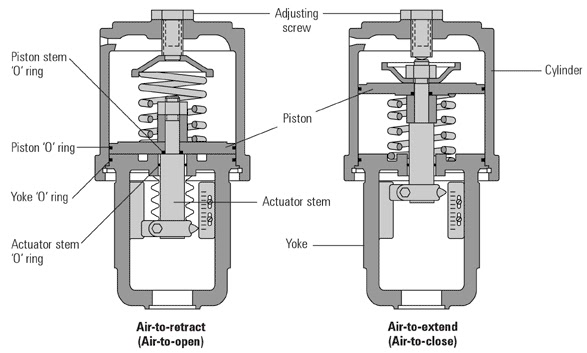

2-1) The piston-style pneumatic actuator utilizes a piston inside a cylinder. The movement of the piston is caused by applying pneumatic pressure thereby moving the piston upwards.

Removing the pneumatic pressure causes the piston to move downward due to the pressure of the spring. This motion is referred to as Air-to-Retract. An Air-to-Extend motion can be also be achieved by rearranging the spring, piston, and pneumatic supply.

2-2) The spring/diaphragm pneumatic actuator is probably the most common actuator used to operate industrial process control valves. So, let’s have a closer look.

The spring/diaphragm pneumatic actuator consists of a diaphragm and plate that are connected to an actuator stem. A flexible diaphragm is enclosed in pressure-tight housing.

Pneumatic pressure enters this housing applying pressure to the diaphragm. As the air pressure increases to the diaphragm the force exerted against the spring increases causing the actuator stem to move.

Reducing the pneumatic pressure will cause the spring to retract the diaphragm. The actuator stem will move a valve in or out of a valve body.

we’re going to talk about pneumatic actuators. We’ll look closely at the operation and application of the most common pneumatic actuator, the spring/diaphragm linear pneumatic actuator.

An actuator is a device that makes something move or operate. Actuators make life easier for us every day, and they are the workhorses of the industry.

There are three typical types of actuators used in industry as defined by their energy source:

– Electric

– Hydraulic,

– Pneumatic.

A pneumatic actuator converts energy in the form of compressed air into movement. Pneumatic actuators are categorized by their type of motion. They are either Linear or Rotary.

1) A rotary pneumatic actuator can make something move in a circular motion. For example, a rod in a rack and pinion drive system is used to produce rotary motion.

In the Rotary pneumatic actuator category, the Vane style and the Rack and Pinion style are very common.

1-1) Vane Actuators have a cylindrical chamber in which a movable vane is mounted on a shaft. Pneumatic air under pressure applied on one side of the vane causes it to rotate through its stroke.

1-2) Rack and Pinion actuators use a piston attached to rack gear. When pneumatic pressure is applied, the piston and rack move linearly rotating the pinion gear and driveshaft.

2) A linear pneumatic actuator can move something in a straight line. For example, a rod is moved in and out of a cylinder in a linear motion by a pneumatic energy source. In the Linear pneumatic actuator category, the spring/diaphragm style and the piston style are very common.

2-1) The piston-style pneumatic actuator utilizes a piston inside a cylinder. The movement of the piston is caused by applying pneumatic pressure thereby moving the piston upwards.

Removing the pneumatic pressure causes the piston to move downward due to the pressure of the spring. This motion is referred to as Air-to-Retract. An Air-to-Extend motion can be also be achieved by rearranging the spring, piston, and pneumatic supply.

2-2) The spring/diaphragm pneumatic actuator is probably the most common actuator used to operate industrial process control valves. So, let’s have a closer look.

The spring/diaphragm pneumatic actuator consists of a diaphragm and plate that are connected to an actuator stem. A flexible diaphragm is enclosed in pressure-tight housing.

Pneumatic pressure enters this housing applying pressure to the diaphragm. As the air pressure increases to the diaphragm the force exerted against the spring increases causing the actuator stem to move.

Reducing the pneumatic pressure will cause the spring to retract the diaphragm. The actuator stem will move a valve in or out of a valve body.

No comments:

Post a Comment